From Plant to Pattern: The Story of Jute, Bangladesh's "Golden Fiber"

Do you ever wonder what makes Bangladesh special to the global economy? One word: Jute.

This amazing plant turned a simple delta nation into a global powerhouse. The story of jute in Bangladesh is about resilience, culture, and a fiber that shines like gold.

But what exactly is it? Why do we call it the "Golden Fiber"? And why are modern scientists and engineers suddenly obsessed with this ancient crop?

Let me take you on a journey from the muddy fields of Faridpur and Rangpur to the high-fashion runways of the world. You will discover why millions of families depend on this plant today.

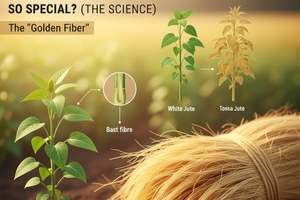

What Makes Jute So Special? (The Science)

Jute is a natural plant fiber derived from the Corchorus plant. It grows tall, strong, and fast.

When you touch raw jute, it feels soft but tough. It shines with a natural, silky luster. This distinct color is why the world calls it the "Golden Fiber."

The Botanical Breakdown

Source: It is a bast fiber, meaning it comes from the inner bark of the plant's stem.

Varieties: Bangladesh primarily grows two types:

White Jute (Corchorus capsularis) and the premium Tossa Jute (Corchorus olitorius). Tossa is softer, silkier, and stronger, commanding a higher price in export markets.

Usage: It is the second most important vegetable fiber in the world by production volume, right after cotton.

How Jute Built Bangladesh's Economy: A Global Cash Crop

Jute is not just a crop; it is the backbone of our economy. The history of jute is intertwined with the industrialization of the subcontinent.

The Historical Anchor: Narayanganj

In the 19th century, British jute barons recognized the quality of Bengal jute. They set up processing mills in Narayanganj, turning it into the financial and industrial center for jute. Narayanganj earned the title "Dundee of the East"—a powerful semantic entity that links local industry to global commerce. During both World Wars, millions of sandbags were fabricated from Bengal jute, demonstrating its strategic military and industrial importance.

The Economic Impact Today (FY 2024–2025)

Even in the age of synthetics, the economic contribution is undeniable:

Livelihood: Roughly 40 million people in Bangladesh depend directly or indirectly on the jute sector for their livelihood, encompassing farmers, mill workers, and exporters.

Exports (FY 2024–2025): The Khulna region alone earned Tk 5,971.40 crore by exporting raw jute and jute goods, showing the increasing global flow of export orders for environment-friendly products.

Global Ranking: Bangladesh is the second-largest producer of jute but the largest exporter of raw jute fiber in the world. We consistently account for over 70% of global raw jute exports.

Identity: The plant's leaves are featured on the National Emblem of Bangladesh, signifying its essential status.

From Seed to Sack: The Jute Journey (Detailed Process)

How does a green plant turn into a strong rug? The process is fascinating and relies heavily on the unique Ganges Delta geography.

Step 1: Cultivation (The Regional Context)

Farmers plant seeds between March and June. The suitable climate (20°C to 40°C) and the alluvial soil of the delta are perfect.

Jat Area: This central region (Dhaka, Mymensingh, Comilla) receives annual silt deposits, yielding the best quality jute.

District Area: Regions like Kushtia and Jessore produce high-quality jute that is slightly tougher.

Northern Area: Districts like Dinajpur and Rangpur, located near the Teesta river silt, produce jute with lower moisture retention.

Step 2: Harvesting & Retting (The Critical Step)

When flowers appear, workers cut the stalks. Then comes the most important part: Retting.

What is Retting? Farmers bundle the stalks and submerge them in slow-moving water for about 20 days.

The Biology: This natural fermentation process softens the woody outer bark (hurd) and allows the bast fibers to be easily separated. Clear, slow-flowing water is essential for good retting.

Step 3: Stripping & Drying (The Zero-Waste Model)

Workers stand in waist-deep water to strip the fibers from the core stick (called the Paat Khori).

Washing: The fibers are washed in clear water.

Zero-Waste: The leaves are eaten as the nutritious "Paat Shak" (a beloved Bengali dish), and the Paat Khori stick is later used as rural cooking fuel and fencing.

Step 4: Grading & Baling

Not all fiber is equal. Fibers are graded based on color, strength, and length.

Export Grading: Fibers are compressed into Pucca Bales and graded using specific industry terms like Bangla Tossa (premium) or Bangla White (standard).

Step 5: Spinning & Weaving (From Fiber to Fabric)

The dried fiber is sent to mills where machines comb and spin it into strong yarn. This yarn is woven into fabrics:

Hessian: A plain woven, superior quality fabric (also known as burlap).

Sacking Cloth: A more loosely woven, heavy cloth used for packing.

CBC (Carpet Backing Cloth): Used worldwide as the durable backing for tufted carpets.

How Jute Saves Our Planet (The Eco-Hero Deep Dive)

In a world drowning in plastic, jute is the savior we need. It possesses unique environmental advantages that make it a champion of climate-smart agriculture.

Carbon Sequestration: The Jute Advantage

The Fact: One hectare of jute plants consumes 15 tons of Carbon Dioxide and releases 11 tons of Oxygen in just 120 days. This is a powerful carbon sink that helps mitigate global warming.

Comparison: Cotton only sequesters around 3 - 4 tons of CO₂ per hectare. Jute's rapid growth and dense canopy give it this photosynthetic advantage.

Biodegradability & Waste Management

The Fact: Plastic bags take up to 2,000 years to decompose. A jute bag biodegrades naturally in 1-2 years, enriching the soil with nutrients (humus and micronutrients) as it rots. This makes it a perfect component of the circular economy.

Chemical Use: Jute cultivation is less dependent on chemical fertilizers and pesticides compared to other commercial crops, further reducing its environmental footprint.

Jute vs. Cotton vs. Plastic (The Data)

The Future: Innovation and Global Impact

The "Golden Fiber" is getting a modern makeover, moving into high-tech and high-fashion markets.

1. Jute Geo-textiles (JGT)

Engineers now use jute netting to stop soil erosion on riverbanks, hill slopes, and during road construction.

How it works: The netting stabilizes the soil while local vegetation takes root. Once the plants grow strong, the jute biodegrades naturally, leaving no residue. This is the definition of Eco-Engineering.

2. The "Sonali Bag" (Jute Bioplastic)

This is a revolutionary invention from Bangladesh. Scientist Dr. Mubarak Ahmad Khan invented a bag that looks and feels like plastic but is made from jute cellulose.

Significance: It is 100% compostable and dissolves in water. This innovation is Bangladesh's most powerful tool to help replace single-use plastics globally.

3. Jute in High Fashion and Composites

Designers are blending jute with soft cotton to create "Jutin" fabric, used for stylish jackets and luxury handbags. Furthermore, jute fibers are being used as reinforcement in car interiors (replacing fiberglass) and construction materials, improving fuel efficiency and sustainability.

Experience the Golden Fiber: Jute Products for Modern Living

This journey proves that jute is a modern marvel. At Kaaruj, we blend this traditional fiber with contemporary design.

1. Hand-Woven Jute Rugs

Our rugs showcase jute's high tensile strength. They are durable and perfect for the high-traffic areas of your home.

Explore: [Shop Jute Rugs & Runners]

2. Eco-Friendly Table Decor

Our placemats and runners protect your wooden furniture from heat and moisture—essential for a Bengali dining table.

Explore: [Shop Jute Table Runners]

3. Sustainable Accessories

From braided artisan trays to storage baskets, jute offers a stylish, plastic-free alternative for organizing your home.

Government Policy and Challenges

The Government of Bangladesh supports the sector through the Mandatory Jute Packaging Act, 2010. This law requires essential crops like rice, wheat, and sugar to be packed in jute bags, ensuring a stable market for farmers.

However, challenges remain: modernization of old mills, price instability, and competition from synthetics. But with the global focus on sustainability, the future of the Golden Fiber has never been brighter.

The Golden Thread That Connects Us All

Jute is more than just a fiber. It is a symbol of Bangladesh's resilience, connecting the history of Narayanganj's mills to the future of global climate solutions.

When you choose jute, you choose to support 40 million people, you choose a carbon sink, and you choose the future.

Ready to bring a piece of heritage home? Shop the Authentic Jute Collection at Kaaruj.

🔗 References & Credible Sources

Bangladesh Investment Development Authority (BIDA) - For data on Jute industry overview, economic rankings, and investment.

International Labour Organization (ILO) - For statistics on employment and rural development impact.